SKU:SPMC250

SaporePuro Food Methylcellulose - Thickener and Gelling Agent

SaporePuro Food Methylcellulose - Thickener and Gelling Agent

Share

12 disponibili

Impossibile caricare disponibilità ritiro

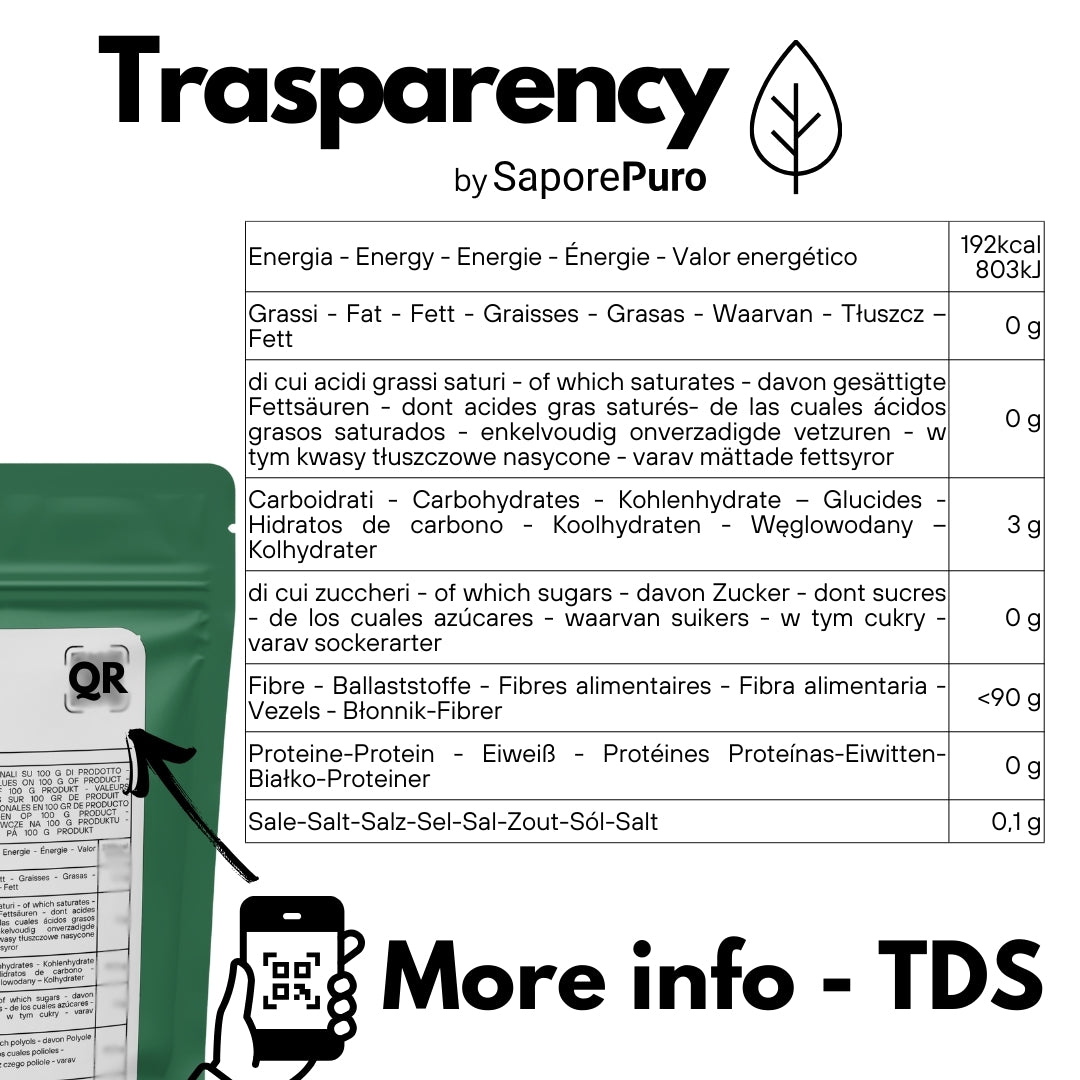

| Product Details | |

|---|---|

Dosage |

0,5% - 3%

|

Origin of raw material |

EXTRA UE

|

Food Needs |

Senza glutine, Vegan e Vegetariana

|

Data Sheet |

|

Fields of use |

Pasticceria, Cosmetici, Cucina del Benessere, Cucina Salutare, Cucina e Prodotti Vegan

|

Moisture |

27.5 - 31.5%

|

Viscosità |

37500 – 70000 mPa.s

|

🧪 Metilcellulosa SaporePuro

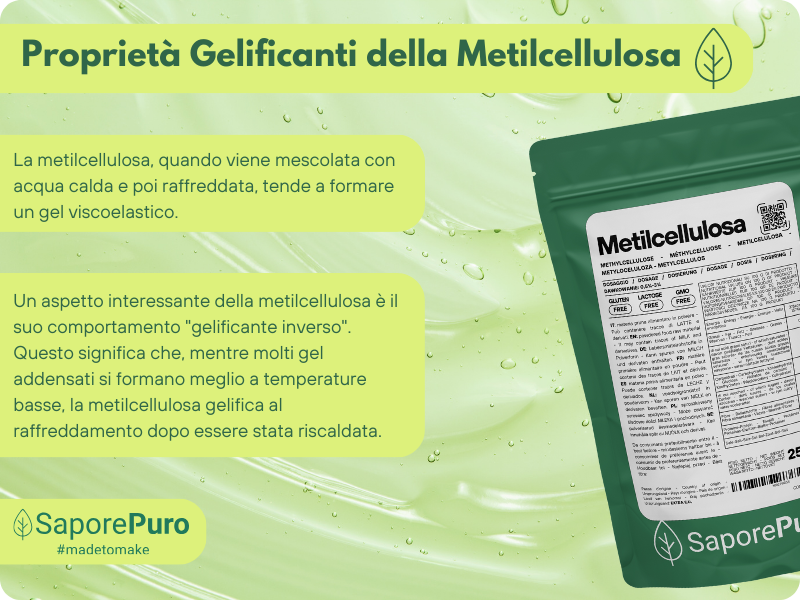

La Metilcellulosa SaporePuro (E461) è una polvere bianca o leggermente crema, disponibile in forma fibrosa o granulare, ampiamente utilizzata nell’industria alimentare grazie alle sue proprietà di addensante, stabilizzante ed emulsionante. Si tratta di un ingrediente funzionale molto versatile, capace di migliorare la consistenza delle preparazioni e di garantire maggiore stabilità.

Oltre all’alimentare, trova impiego anche nel settore farmaceutico (come eccipiente in capsule e compresse) e nella cura personale (gel, lozioni, dentifrici) grazie alla sua capacità di conferire viscosità e stabilità alle formulazioni.

⚙️ Caratteristiche e utilizzi

La Metilcellulosa è apprezzata per la sua capacità di addensare, stabilizzare e migliorare la consistenza di alimenti e preparazioni particolari.

-

Nei prodotti da forno mantiene morbidezza e umidità degli impasti, rendendoli meno secchi o friabili, e migliora la struttura, soprattutto nelle versioni senza glutine.

-

In farine e ripieni aumenta coesione e stabilità, mantenendo la freschezza durante la cottura.

-

Negli alimenti fritti riduce l’assorbimento di grassi, migliora la croccantezza della panatura e garantisce una consistenza più leggera.

-

Nelle bevande aggiunge corpo e viscosità senza calorie, ideale per formulazioni light o funzionali.

-

In burri e creme spalmabili conferisce maggiore stabilità e consistenza.

-

In cucina molecolare è impiegata per creare consistenze gelatinose a caldo che tornano liquide a freddo, perfette per piatti innovativi.

✨ Vantaggi

La Metilcellulosa SaporePuro è una soluzione funzionale versatile che migliora la resa sensoriale e tecnologica dei prodotti alimentari. Tra i suoi principali vantaggi:

-

Maggiore stabilità in salse, zuppe e condimenti.

-

Riduzione dei grassi negli alimenti fritti.

-

Migliore struttura e morbidezza nei prodotti da forno, anche senza glutine.

-

Applicazioni innovative nella cucina molecolare.

📌 Specifiche tecniche

-

Codice additivo: E461

-

Aspetto: polvere bianca o crema

-

Solubilità: solubile in acqua

🍴 Ricetta con Metilcellulosa SaporePuro

Nuggets vegetariani al tofu

-

200 g di tofu sgocciolato

-

100 g chopped mushrooms

-

1 teaspoon of Methylcellulose FlavorPure

-

100 ml of cold water

-

Sale e spezie a piacere

-

Pangrattato per la panatura

Preparazione: idratare la metilcellulosa con acqua fredda e lasciare riposare 5 minuti. Frullare tofu e funghi, aggiungere il gel di metilcellulosa e condire. Formare i nuggets, passarli nel pangrattato e friggere fino a doratura.

🗄️ Conservazione

Conservare la Metilcellulosa SaporePuro in contenitori ben chiusi, lontano da luce e umidità, a temperatura ambiente. In questo modo mantiene le sue proprietà fino alla data di scadenza.

-

Delivery Guarantee

All orders are processed in 24/48h and delivered by your preferred courier service.

Whatsapp and Email notifications with tracking. -

Secure Payments

Multiple payment options available. Your details are securely encrypted within the latest technologies.

-

Certified Quality

All SaporePuro ingredients are certified according to EU regulations. We guarantee only the highest quality and certified origins.

-

Assistenza Rapida

Non vi lasciamo mai soli. Il nostro team di assistenza clienti è disponibile7 giorni su 7 per garantirti un'esperienza d'acquisto senza intoppi.

Ingredienti professionali, consegne rapide, zero pensieri.

SaporePuro è lo shop online per professionisti e casalinghi: centinaia di ingredienti tecnici, spedizioni veloci e supporto dedicato.